Have you ever wondered what makes racing so exhilarating? It’s not just the roar of engines or the thrill of high-speed chases; it’s the brilliant minds behind the machines. Engineers play a pivotal role in shaping the future of motorsports, from F1 to MotoGP. Their innovative designs and cutting-edge technologies are the backbone of speed and performance on the track.

Take a moment to appreciate the intricate relationship between engineering and racing. Engineers meticulously analyze every component of a vehicle, ensuring that each part works in harmony to achieve maximum efficiency. Imagine a symphony where every instrument contributes to a breathtaking performance; that’s how engineers orchestrate the perfect racing machine.

From the sleek curves of a car’s body to the powerful engines that propel them forward, every detail is crafted with precision. Innovations like active suspension systems and advanced telemetry allow teams to gather real-time data, making split-second decisions that can mean the difference between victory and defeat. The excitement of motorsports is amplified by these technological marvels, which continuously push the limits of what’s possible.

So, whether you’re a die-hard fan or a casual observer, next time you watch a race, remember the engineers working tirelessly behind the scenes. Their passion and expertise not only enhance speed but also ensure that the thrill of racing remains alive. Buckle up, because the world of racing is a never-ending journey of innovation!

Innovative Materials in Racing Engineering

In the fast-paced world of motorsports, where every millisecond counts, the materials used in racing vehicles are nothing short of revolutionary. Imagine a car that feels as light as a feather yet is as strong as a steel fortress. This is the magic of carbon fiber and titanium, two materials that have transformed the racing landscape, particularly in high-stakes competitions like Formula 1 and MotoGP.

Carbon fiber, with its incredible strength-to-weight ratio, allows engineers to create chassis and body panels that are both lightweight and durable. This means that racing teams can achieve higher speeds without compromising safety. On the other hand, titanium, known for its resilience and ability to withstand extreme temperatures, is often used in exhaust systems and engine components, ensuring that these critical parts endure the intense conditions of a race.

The integration of these materials not only enhances speed but also contributes to fuel efficiency. A lighter vehicle requires less energy to accelerate, which can be a game-changer during long races. To put it into perspective, consider how a feather floats effortlessly in the air compared to a brick sinking like a stone. That’s the difference these materials make on the racetrack.

As engineers continue to push the envelope, we can expect even more innovative materials to emerge, further enhancing the performance and safety of racing vehicles. The future of racing engineering is not just about going fast; it’s about crafting the perfect blend of speed, efficiency, and safety.

Aerodynamics: The Key to High-Speed Performance

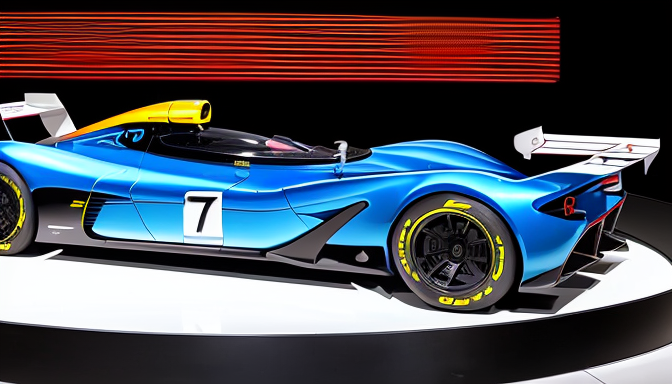

When it comes to racing, speed isn’t just about raw power; it’s also about how well a vehicle can cut through the air. This is where aerodynamics steps in, playing a pivotal role in determining a car’s performance on the track. Imagine trying to run through water—it’s tough, right? Now, picture a car facing the same challenge but with air. Engineers meticulously design vehicles to reduce drag and enhance downforce, allowing them to glide effortlessly at high speeds.

Take Formula 1, for instance. The sleek designs of these cars aren’t just for show; they are the result of extensive wind tunnel testing and computer simulations. By optimizing the shape of the car, engineers can ensure that it slices through the air with minimal resistance. This means that the car can maintain higher speeds while also achieving better stability during sharp turns. The balance between downforce and drag is crucial, as too much downforce can slow a car down, while too little can lead to loss of control.

To truly appreciate the impact of aerodynamics, consider the following factors:

- Drag Coefficient: A lower drag coefficient means less air resistance.

- Downforce: Increased downforce improves tire grip, allowing for higher cornering speeds.

- Body Shape: Streamlined shapes reduce turbulence and enhance airflow.

In essence, the art of aerodynamics is like crafting a perfect dance between speed and control. As engineers continue to innovate, we can expect even more exhilarating performances on the track, pushing the boundaries of what’s possible in motorsports.

Frequently Asked Questions

- What materials are commonly used in racing vehicles?

Racing engineers often use advanced materials like carbon fiber and titanium. These materials are incredibly lightweight yet strong, allowing for faster speeds and better handling on the track.

- How does aerodynamics affect racing performance?

Aerodynamics is crucial in racing. Engineers design vehicles to reduce drag and enhance downforce, which helps maintain stability and speed, especially during sharp turns and high-speed maneuvers.

- What role do engineers play in a racing team?

Engineers are the backbone of a racing team. They analyze data, optimize vehicle performance, and implement innovative technologies to ensure the car is as fast and efficient as possible on the track.

- Can the public access racing technology?

Absolutely! Many racing technologies eventually trickle down to consumer vehicles. Innovations in materials and aerodynamics often influence the design of everyday cars, making them safer and more efficient.